KEY ADVANTAGES

Extension of the asset's lifecycle from 5 to 30 times compared to carbon steel, depending on coating thickness and flow parameters

Outstanding corrosion and erosion protection

Multiple re-lining and re-using of spools

Significantly extended maintenance intervals

Immunity to vacuum conditions or cleaning operations due to adhesion between coating and steel substrate

Integration of thermal insulation within the line

Resistance against cold-wall effect due to good thermal insulation and strong bonding to wall

Even and smooth surface for low friction coefficients and reduced pump energy consumption

RoCoat™ field joint coupling: approved system for welding-coated pipe joints in the field

Suitable for a variety of pipe connections such as flange, pin-in-Box, quick couplings, Victaulic (C), and many more.

THE SOLUTION

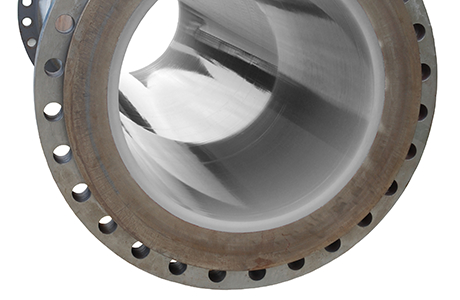

RoCoat™ protected pipes and fittings are currently used in applications such as hydro transportation lines, slurry lines, water injection pipes, dredging, tailings lines, and power plant piping. RoCoat™ is available for pipe diameters from 4" (DN 100) to 48" (DN 1230) and for pipe lengths from two meters (six feet) and less up to eighteen meters (fifty-nine feet).

In addition to straight spools, ROSEN is able to apply coating on elbows, extension barrels, reducers, T- or Y-pieces and fittings. ROSEN IPS provides a full-value package of all related engineering services, material/pipe acquisition, documentation, packaging, logistics, and on-site assembly.

Interested in intelligent Coatings? Find out more about our Wear Monitoring System.

Extension of the asset's lifecycle from 5 to 30 times compared to carbon steel, depending on coating thickness and flow parameters

Outstanding corrosion and erosion protection

Multiple re-lining and re-using of spools

Significantly extended maintenance intervals

Immunity to vacuum conditions or cleaning operations due to adhesion between coating and steel substrate

Integration of thermal insulation within the line

Resistance against cold-wall effect due to good thermal insulation and strong bonding to wall

Even and smooth surface for low friction coefficients and reduced pump energy consumption

RoCoat™ field joint coupling: approved system for welding-coated pipe joints in the field

Suitable for a variety of pipe connections such as flange, pin-in-Box, quick couplings, Victaulic (C), and many more.

THE SOLUTION

RoCoat™ protected pipes and fittings are currently used in applications such as hydro transportation lines, slurry lines, water injection pipes, dredging, tailings lines, and power plant piping. RoCoat™ is available for pipe diameters from 4" (DN 100) to 48" (DN 1230) and for pipe lengths from two meters (six feet) and less up to eighteen meters (fifty-nine feet).

In addition to straight spools, ROSEN is able to apply coating on elbows, extension barrels, reducers, T- or Y-pieces and fittings. ROSEN IPS provides a full-value package of all related engineering services, material/pipe acquisition, documentation, packaging, logistics, and on-site assembly.

Interested in intelligent Coatings? Find out more about our Wear Monitoring System.