KEY ADVANTAGES

Improved sizing accuracy and probability of identification by combining complementary inspection technologies and aligned data sets

Improved characterization of interacting defects, e.g. gouging/denting, corrosion/cracks in dents

Cost-effectiveness and reduction of operational risks by limiting onsite activities, e.g. launching, receiving and tool tracking

Reduced impact on pipeline operations

THE SOLUTION

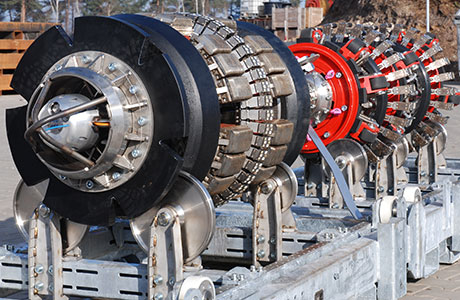

ROSEN provides a variety of different and well-established inspection technologies to address a multitude of threats. Our modular design allows for unlimited combinations of our individual services. The modularity is supported by standardized mechanics and electronics interfaces.

Multiple inspection data is input for our combined data analysis using synergy effects of the independent and complementary nature of the measurements. Using a well-structured and certified process our analysts provide the required high-quality reports on time.

The reporting and data management software ROSOFT ensures easy data visualization and facilitates a versatile use of inspection results.

SERVICE OPTIONS

Cleaning – operational and pre inspection

Speed Control – inspection at high flow rates

Multi-Diameter – pipelines with varying diameter

Offshore – long distance, heave wall and high pressure

Field Verification – 3D LaserScan, MPI, phased array UT

Integrity – RBI, FFP, CGA, dent strain and stress analysis, crack assessment API 579

ROAIMS – versatile asset integrity software suite

Improved sizing accuracy and probability of identification by combining complementary inspection technologies and aligned data sets

Improved characterization of interacting defects, e.g. gouging/denting, corrosion/cracks in dents

Cost-effectiveness and reduction of operational risks by limiting onsite activities, e.g. launching, receiving and tool tracking

Reduced impact on pipeline operations

THE SOLUTION

ROSEN provides a variety of different and well-established inspection technologies to address a multitude of threats. Our modular design allows for unlimited combinations of our individual services. The modularity is supported by standardized mechanics and electronics interfaces.

Multiple inspection data is input for our combined data analysis using synergy effects of the independent and complementary nature of the measurements. Using a well-structured and certified process our analysts provide the required high-quality reports on time.

The reporting and data management software ROSOFT ensures easy data visualization and facilitates a versatile use of inspection results.

SERVICE OPTIONS

Cleaning – operational and pre inspection

Speed Control – inspection at high flow rates

Multi-Diameter – pipelines with varying diameter

Offshore – long distance, heave wall and high pressure

Field Verification – 3D LaserScan, MPI, phased array UT

Integrity – RBI, FFP, CGA, dent strain and stress analysis, crack assessment API 579

ROAIMS – versatile asset integrity software suite