KEY ADVANTAGES

High dependable detection and accurate continuous sizing of all critical crack anomalies.

Coating disbondment as precursor of cracking is reliably detected by the ROSEN EMAT technology.

Application in all pipeline products, e.g. natural gas, LNG, crude oil and gasoline due to the fundamental EMAT principle.

High availability and a wide range of proven tool configurations addressing individual operational pipeline requirements.

High quality service with certified processes (API 1163), personnel qualification (ASNT) and equipment (CE, ATEX).

THE SOLUTION

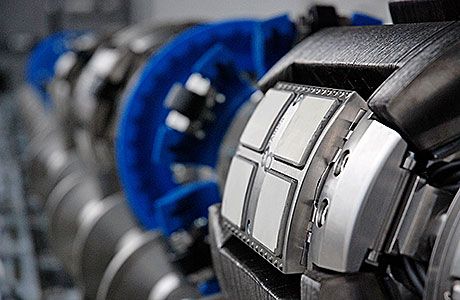

ROSEN uses an innovative inspection technology to couple ultrasonic energy into the pipe wall without the need for a liquid medium. This makes our EMAT technology the first choice for crack inspection of gas pipelines. Accurate sizing of any crack depth is made possible by the right selection of special EMAT wave modes.

Our well–structured, certified data evaluation process enables ROSEN’s data analysts to provide the required high quality assessment on-time. The accuracy of the findings is supported by our large in-house crack database and repository.

The reporting software ROSOFT facilitates the broad use of the inspection results.

SERVICE OPTIONS

Cleaning – operational and pre inspection

Speed Control – inspection at high flow rates

XYZ – route mapping and strain analysis

Dual-Diameter – pipelines with varying diameter

Combo – multiple inspection technologies in one run

Offshore – long distance and high pressure

Post ILI – data alignment and combined evaluation

Field Verification – MPI, phased array UT

Integrity – RBI, FFP, crack assessment API 579

ROAIMS – versatile asset integrity software suite

High dependable detection and accurate continuous sizing of all critical crack anomalies.

Coating disbondment as precursor of cracking is reliably detected by the ROSEN EMAT technology.

Application in all pipeline products, e.g. natural gas, LNG, crude oil and gasoline due to the fundamental EMAT principle.

High availability and a wide range of proven tool configurations addressing individual operational pipeline requirements.

High quality service with certified processes (API 1163), personnel qualification (ASNT) and equipment (CE, ATEX).

THE SOLUTION

ROSEN uses an innovative inspection technology to couple ultrasonic energy into the pipe wall without the need for a liquid medium. This makes our EMAT technology the first choice for crack inspection of gas pipelines. Accurate sizing of any crack depth is made possible by the right selection of special EMAT wave modes.

Our well–structured, certified data evaluation process enables ROSEN’s data analysts to provide the required high quality assessment on-time. The accuracy of the findings is supported by our large in-house crack database and repository.

The reporting software ROSOFT facilitates the broad use of the inspection results.

SERVICE OPTIONS

Cleaning – operational and pre inspection

Speed Control – inspection at high flow rates

XYZ – route mapping and strain analysis

Dual-Diameter – pipelines with varying diameter

Combo – multiple inspection technologies in one run

Offshore – long distance and high pressure

Post ILI – data alignment and combined evaluation

Field Verification – MPI, phased array UT

Integrity – RBI, FFP, crack assessment API 579

ROAIMS – versatile asset integrity software suite