By reducing turbulence and shear forces in valves downstream separation efficiency is improved. Typhoon® Valve System is a low shear valve technology developed by Typhonix and the result of a 12 million dollar development program sponsored by Shell, Statoil, Eni, Total, ConocoPhillips, GDF SUEZ, Mokveld and the Research Council of Norway. The Typhoon® System is a cost efficient way to debottleneck your separation and produced water treatment system, without adding additional equipment.

TYPHOON® VALVE SYSTEM:

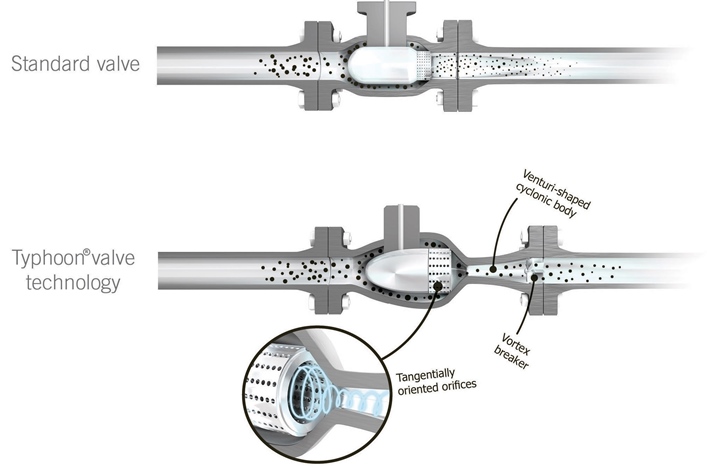

Typhoon® Valve System is developed to reduce shear forces and thereby droplet break-up and emulsification of oil and water. Typhoon® Valve System has, through several years of experimental investigations, documented a significant positive effect on downstream separation, improving oil and water quality. Typhoon® Valve System can replace both a conventional choke and control valves.

USER BENEFITS:

The business benefits of using Typhoon® Valve System are:

Improved oil and water quality

Cost efficient separation system debottlenecking

More compact separation systems

Increase separator capacity

Longer production of high WC wells

Reduced need for separation enhancing production chemicals

The Typhoon® Valve System is designed and manufactured by the leading international supplier, Mokveld Valves BV. Typhoon® Valve System is designed to easily replace conventional chokes or control valves, both axial and angled valves.

Replacing today’s conventional valves with the new Typhoon® Valve System offers a cost efficient solution to enhance separation efficiency and reduce environmental impact with regards to produced water discharge.

WHERE TO USE IT?

Typhoon® Valve System is a flow control system like any conventional choke or control valve. Typhoon® Valve System is therefore considered for use in all applications where standard valves are used today. In optimizing oil-water separation, Typhoon® System can advantageously replace conventional choke or control valves located upstream main separation equipment or produced water treatment equipment, i.e. upstream large three-phase separators, hydrocyclones, degassers, flotation units, etc.

TYPHOON® VALVE SYSTEM:

Typhoon® Valve System is developed to reduce shear forces and thereby droplet break-up and emulsification of oil and water. Typhoon® Valve System has, through several years of experimental investigations, documented a significant positive effect on downstream separation, improving oil and water quality. Typhoon® Valve System can replace both a conventional choke and control valves.

USER BENEFITS:

The business benefits of using Typhoon® Valve System are:

Improved oil and water quality

Cost efficient separation system debottlenecking

More compact separation systems

Increase separator capacity

Longer production of high WC wells

Reduced need for separation enhancing production chemicals

The Typhoon® Valve System is designed and manufactured by the leading international supplier, Mokveld Valves BV. Typhoon® Valve System is designed to easily replace conventional chokes or control valves, both axial and angled valves.

Replacing today’s conventional valves with the new Typhoon® Valve System offers a cost efficient solution to enhance separation efficiency and reduce environmental impact with regards to produced water discharge.

WHERE TO USE IT?

Typhoon® Valve System is a flow control system like any conventional choke or control valve. Typhoon® Valve System is therefore considered for use in all applications where standard valves are used today. In optimizing oil-water separation, Typhoon® System can advantageously replace conventional choke or control valves located upstream main separation equipment or produced water treatment equipment, i.e. upstream large three-phase separators, hydrocyclones, degassers, flotation units, etc.